![]() Home

Home ![]() Portfolio

Portfolio ![]() Drawing Board

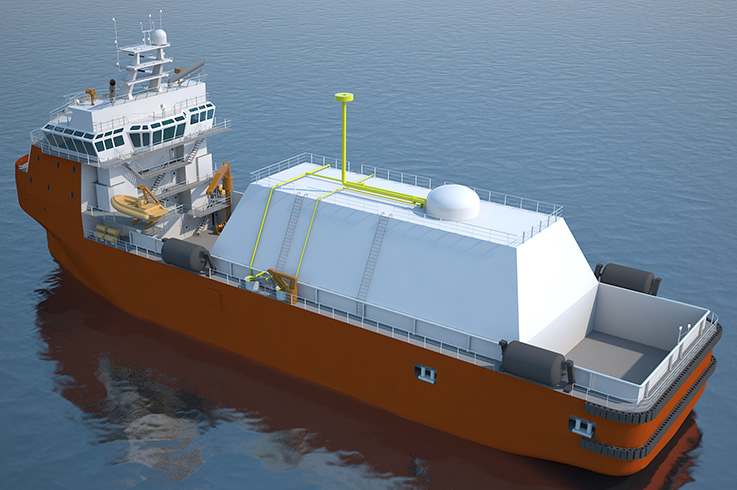

Drawing Board ![]() Conversion Of Existing Laid-up Psv To Lng Bunker Vessel

Conversion Of Existing Laid-up Psv To Lng Bunker Vessel

Small scale LNG is a new concept to operate ‘laid-up’ vessels. A new build has high capex & not viable especially in a new growing market. Due to oil price crash there are hundreds of laid-up OSVs.

They have:

• large deck space

• reasonably high power

• high deck loading capacity

They are now worth the fraction of their building cost.

So NAVNAUTIK is proposing an innovative solution.

They are quite suitable for converting to small scale LNG of:

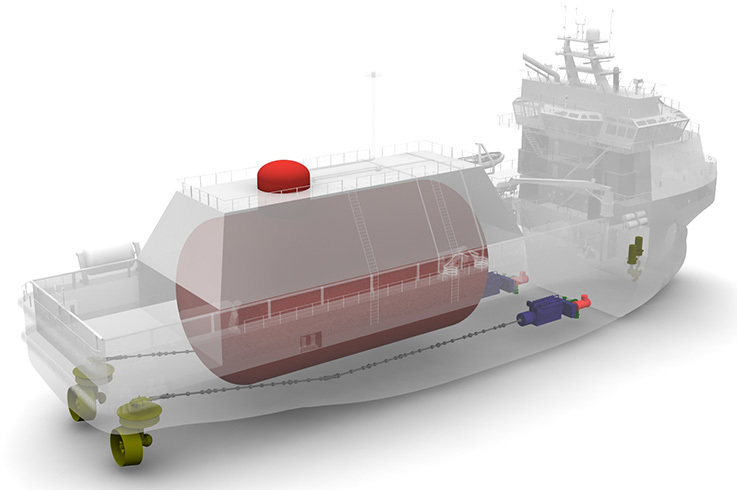

• Deck mounted type C LNG tank cargo containment system having equivalent capacity of original allowable deck load.

• Hold mounted type C LNG tank cargo containment system having equivalent capacity of original dead weight.

Main areas of considerations are:

• Ship’s arrangement.

• Hazardous zone

• Intact stability

• Damage stability

The approach:

Considering that the original OSV had been laid up, the conversion cost is a fraction of that of a new built vessel. Though the capacity is limited by the original vessel’s capacity, considering the cost, a number of vessels can be converted in order to achieve the required total capacity in a certain market situation and still be cost effective. This also allows simultaneous deployment of the vessels in most situations.

Additional Features:

1. SHIP TO SHIP BUNKERING (STS): Most of these OSVs are DP2. This gives them an added capability to provide STS bunkering service & operate outside the port limit.

2. Carriage of MDO/HFO: If the original vessel is a PSV it usually has a capability of substantial FO tank capacity. I that case it can supply both LNG & FO.

3. Supply of LNG to Islands: Standard ISO tank filling facility can be incorporated on board which can be off loaded in an existing wharf facility & no LNG shore facility is required. Empty ISO containers can be retrieved at the same time.

4. Operating in EPA & ECA Areas: Some of these OSVs are fitted with scrubbers in their engine exhaust & have the capability of operating in EPA & ECA areas. These can take advantage in operating in LNG active areas.

FACTORS GOVERNING THE CONVERSION COST:

• Estimated cost of conversion depends on the original configuration & properties of the vessel and feedback from shipyard.

• Cost of LNG cargo containment system & controls to be obtained from vendor.

• Engine relocation / replacement depends upon operator’s requirements – whether to go for Dual-Fuel engines or Pure Gas Engines. Separate cost towards engine modification has to be considered.

Tentatively, the conversion cost should not be more than 10-15% of the vessel’s original building cost subject to detailed analysis at next stage of the project.